Your operator’s favorite tool to do more while lifting less.

READY ON DAY 1

Easy-to-use

FLEXIBLE BOX TYPES & SIZES

ON DEMAND SUPPORT

Adapt Without Limits

Trust every shift with cloud and edge-side tools that give just the right controls to operators, managers, and maintenance.

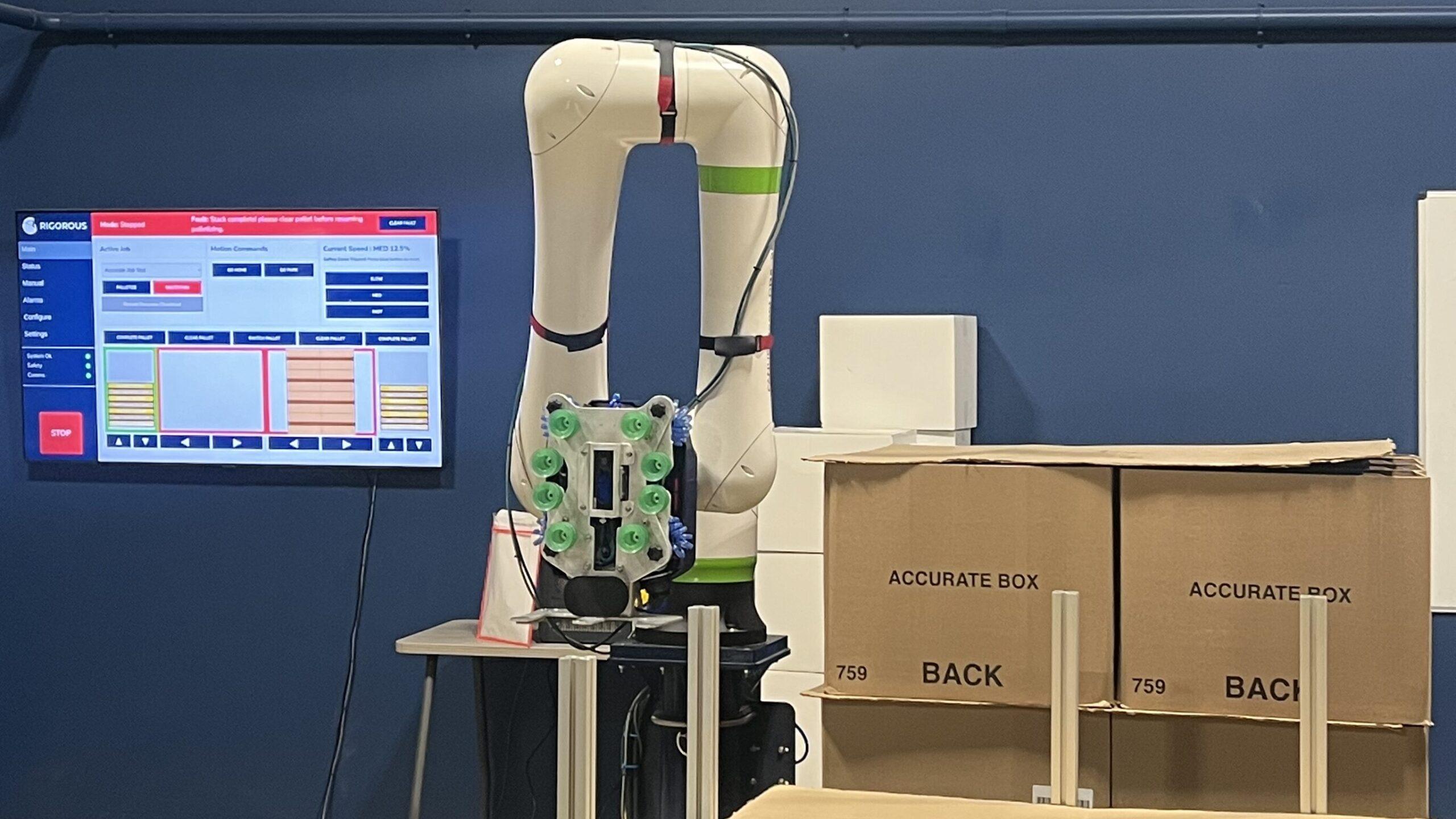

Operators love the intuitive HMI with all (and only) the buttons they need to build stacks of boxes.

Managers rely on productivity insights and analysis that help operators use the RIG more effectively over time.

Process engineers and maintenance gain the flexibility to integrate with existing workflows without costly reprogramming or downtime.

Count on Consistency

The RIG keeps your production flowing, now and into the future.

Don’t get stuck with automation that locks you into a single process. Manage an unlimited number of SKUs and pallet patterns.

With quick redeployment, you can roll the RIG from line to line, based on where you need it most.

Scale Smarter with Full Stack

The most cost-effective way to deploy smart robots at scale across one or more facilities.

The standalone RIG Full Stack software was developed to support in-house engineering groups.

Leverage not only the Palletizing application, but a full library of tools to modify programs, add new hardware components, and back up and restore past programs.

Manage your fleet of robots from one central location while providing your team with the access levels they need to succeed.

Project Outline

Phase 1

Scope

Understand your process, product mix, and goals.

Phase 2

Build

A tailored design for your palletizer.

Phase 3

Deploy

Palletize on day 1, supported for life.

Rapid ROI

The RIG was built for ultimate flexibility, ensuring it works as hard as you do. The more tasks the RIG handles, the faster you’ll see results. Customers often experience a positive return within 1-2 years.

Affordable Automation

With a starting price of $130k and financing options through our lending partner, North Star Leasing, it’s not just a purchase; it’s a smart investment in your business’s future.

Rigorous has been an outstanding partner.

Their intuitive front-end software generates robot code directly within the platform, and their team’s competence, collaborative spirit, and willingness to tackle complex challenges made them feel like part of our engineering department from day one.

Danny Rose

RGS Software Platform

RGS robotic software applications provide seamless integration of advanced sensing technologies and hardware-agnostic controls.

rgsFullStack

A turnkey, configurable, plug-in-ready solution for robotic palletizing.

rgsTrafficController

Material handling and conveyor system controller with Smart Queue technology.

rgsMoves

Efficient path planning for time savings, robot longevity, and obstacle avoidance.

rgsVision

LiDAR and camera vision processing systems to detect inputs inside of the cell and direct action from the robotic system.

On Demand Support

Every great robot is backed by a best-in-class team in the United States.

The RGS support team is remotely monitoring your system and on-call for operator troubleshooting.

We’re here to keep you running.